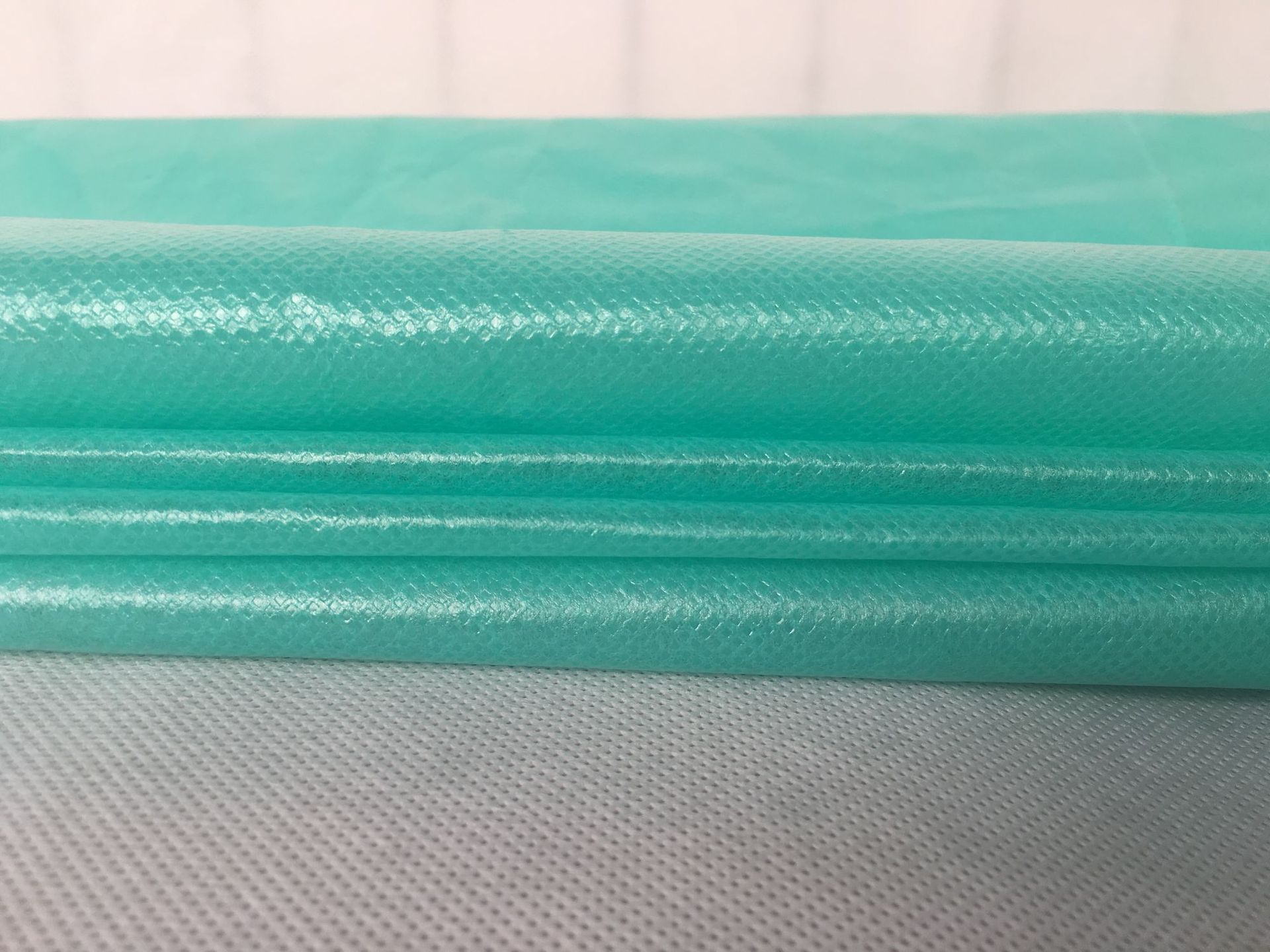

Introduction of coated non-woven fabricLaminating non-woven fabric is also called laminating composite non-woven fabric, this kind of fabric is a new type of fabric. The so-called coated non-woven fabric is to coat a layer of plastic film on the non-woven fabric, which is generally a product formed by coating a plastic film heated to a hot melt state on the non-woven fabric and cooling it. Or a layer of PE material is added to the PP non-woven fabric; it can also be interpreted as a color printing film, which is bonded to the non-woven fabric to express rich colors. Laminated composite non-woven fabrics are more hand-feel than composite non-woven fabrics, and the texture to the touch is stronger than that of laser composite non-woven fabrics. This is a new variety! The best material for making eco-friendly bags! A must-have choice for packaging.

Cloth texture

There are dozens of patterns of embossed non-woven fabrics on the market now, such as checkered pattern/bark pattern/small hole pattern/pinhole pattern/pod pattern/rat pattern/drawing pattern/crocodile pattern/stripe pattern/ Mouth pattern/dot pattern/cross pattern, etc.

Features of coated non-woven fabric

Laminated non-woven fabrics are made of PP, PE and other materials as the waterproof layer, and high-strength non-woven fabrics as the supporting layer, using the laminating process. At the same time, it can give the material color, antibacterial, water absorption and other functions. The material has:

1. Air permeability: It has excellent and uniform air permeability, effectively isolates moisture, and discharges heat and moisture.

2. Softness: It has an excellent hand feeling, which makes the product more soft and comfortable.

3. Mechanical properties: excellent tensile and elongation properties.

4. Chemical properties: not easy to corrode, simple printing, light and high temperature resistance.

5. Waterproof, liquidproof, breathable, environmentally friendly and high strength.

Composite non-woven fabric is a new type of packaging material. The non-woven fabrics and other fabrics can be treated in multiple ways, such as coating treatment, hot pressing treatment, spray treatment, ultrasonic treatment, etc. Through compound treatment, two or three layers of fabrics can be compounded together to produce products with special functions, such as high strength, high water absorption, high barrier properties, and high hydrostatic pressure resistance.

Laminated composite non-woven fabrics are widely used, mainly in the fields of medical treatment, hygiene, protection, industry and automobile industry.

To put it simply, the coated non-woven fabric is not interwoven and knitted together one by one yarns, but the fibers are directly bonded together by physical methods, so when you get it in your clothes You will find that you can’t pull out the thread ends. Non-woven fabric breaks through the traditional textile principle, and has the characteristics of short process flow, fast production speed, high output, low cost, wide use, and multiple sources of raw materials.

电话:+860512-57886027

电话:+860512-57886027 邮箱:

邮箱: 地址: Room 1902, XinDuYinZuo, No. 177, Changjiang Middle Road, Kunshan, Jiangsu

地址: Room 1902, XinDuYinZuo, No. 177, Changjiang Middle Road, Kunshan, Jiangsu